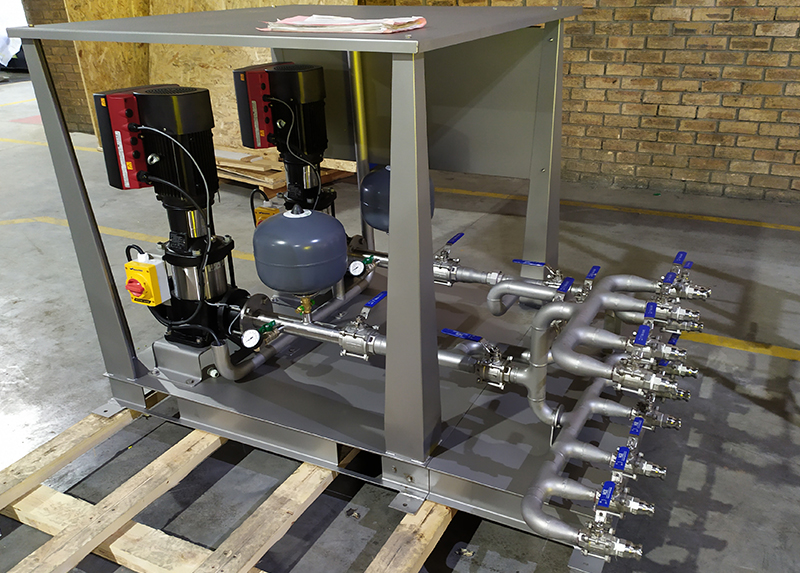

Our capable team can assemble, install, test, and integrate critical assemblies, with additional value-adding services including precision welding, coating, bead blasting, and tumbling.

Our in-house drawing office provides technical drawings with assistance from the concept stage right to complete manufacturing drawings for production.

Committed to Superior Quality

Our Services Include

Machines

-

- 6-axis, TIG and MIG

- 500kg turn & tilt manipulator

- Track mounted welding stations

- Stainless Steel and Mild Steel welding only

Value-added Services

Surface Finishings

The Fabrinox Finish

Material: Stainless Steel

Maximum width: 400mm

Maximum length: 1400mm

Tumbling & Burnishing

Material: Stainless Steel, Mild Steel, Aluminium, 3CR12, Copper, Brass

Maximum width: up to 400mm

Maximum length: up to 1400mm

Sanding

Machine: Belt Sanders

Material thickness: up to 220mm

Maximum width: up to 4000mm

Bead Blasting

Booth size: 4000 x 4000 x 6000mm

Material: Stainless Steel, Aluminium

Acid Bath

Pickle and Passivate

Bath size: 2000 x 2000 x 600mm

DeBurring and Brushing

Machine: Weber DeBurring machine Model TT – 1P

Functionality: Brush, Grind, Deburr, Scotchbrite

Material thickness: 0.8mm – 100mm

Maximum width: up to 1250mm

Spray Painting

Booth size: 6800 x 4000 x 2700mm

Booth loading capacity: 3000kg

Climate-controlled paint storage area

Powder Coating

Maximum size: 6900mm x 2500mm x 2800mm

Material: Stainless Steel, Mild Steel, Aluminium