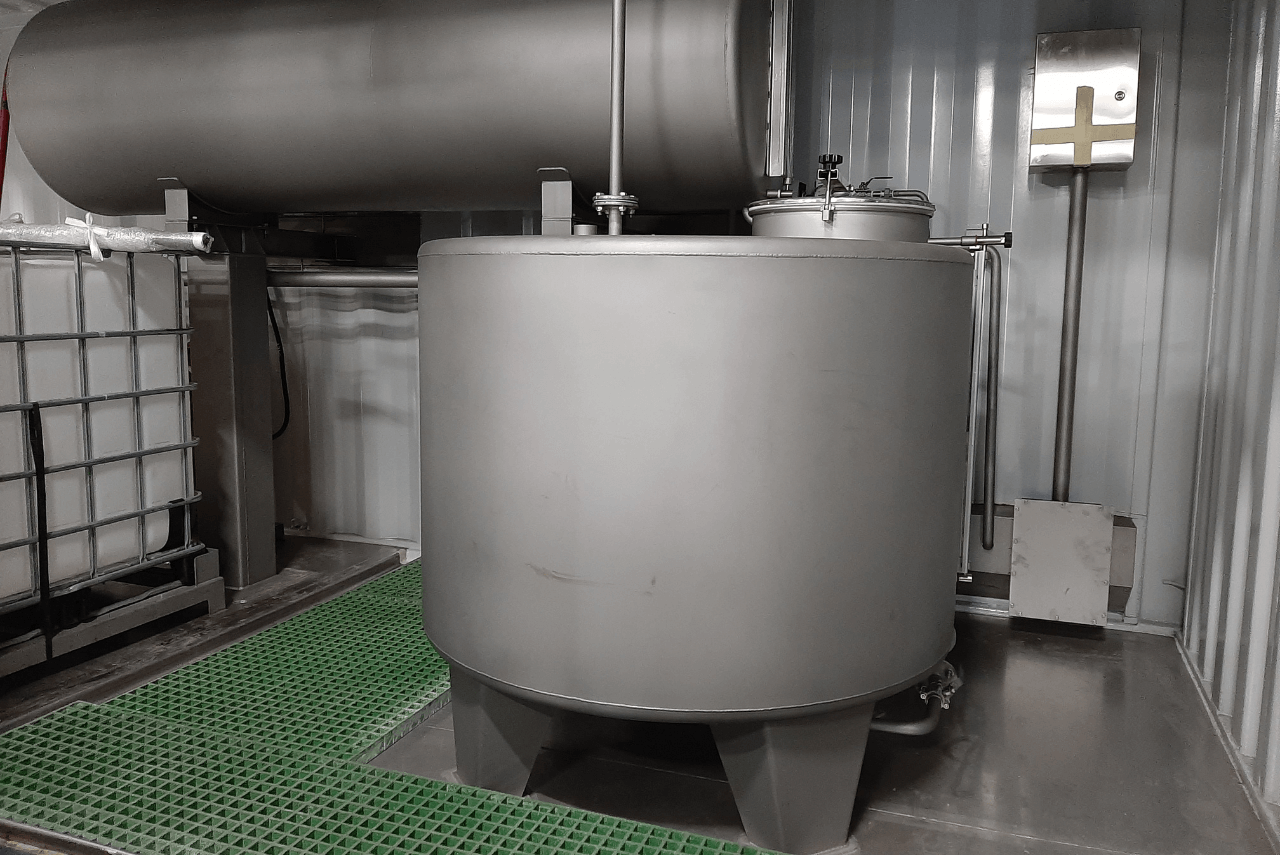

Customer-Centred, Tailor-Made Fabrication Solutions

At Fabrinox, our approach to fabrication is simple: every customer is unique, so every solution should be too. Our Sub-Assembly Department is dedicated to providing solutions that are customised to your exact requirements, helping you achieve greater efficiency, consistency, and product quality.

By combining skilled craftsmanship with leading-edge technology, we deliver cost-effective, value-adding services that streamline production and enhance your product’s final performance.

Value-Driven Sub-Assemblies

Our experienced team is equipped to assemble, test, and integrate critical components, offering complete sub-assemblies that are ready for integration into your production line. This full-service approach helps reduce lead times, eliminate rework, and increase manufacturing efficiency from start to finish.

Design Support & Drawing Services

Our in-house drawing office collaborates closely with your team from initial concept through to final production drawings. Whether you’re starting with detailed design specifications or a basic sketch, we help you refine, test, and optimise your idea before it’s placed into production.

Our Drawing Services Include:

- On-site measurement and prototype testing

- Design analysis at component level for optimal material usage

- As-built drawings based on improvements during production

- Fabrication-ready drawings created from 3D models, specifications, or sketches

Precision Batch Manufacturing

We offer batch manufacturing services supported by a wide range of equipment designed for speed, precision, and repeatability. Our robot and spot welders ensure consistent quality, while our laser welders improves efficiency and surface finish.

This capability is ideal for manufacturers seeking reliable, scalable production without compromising on detail or turnaround time.

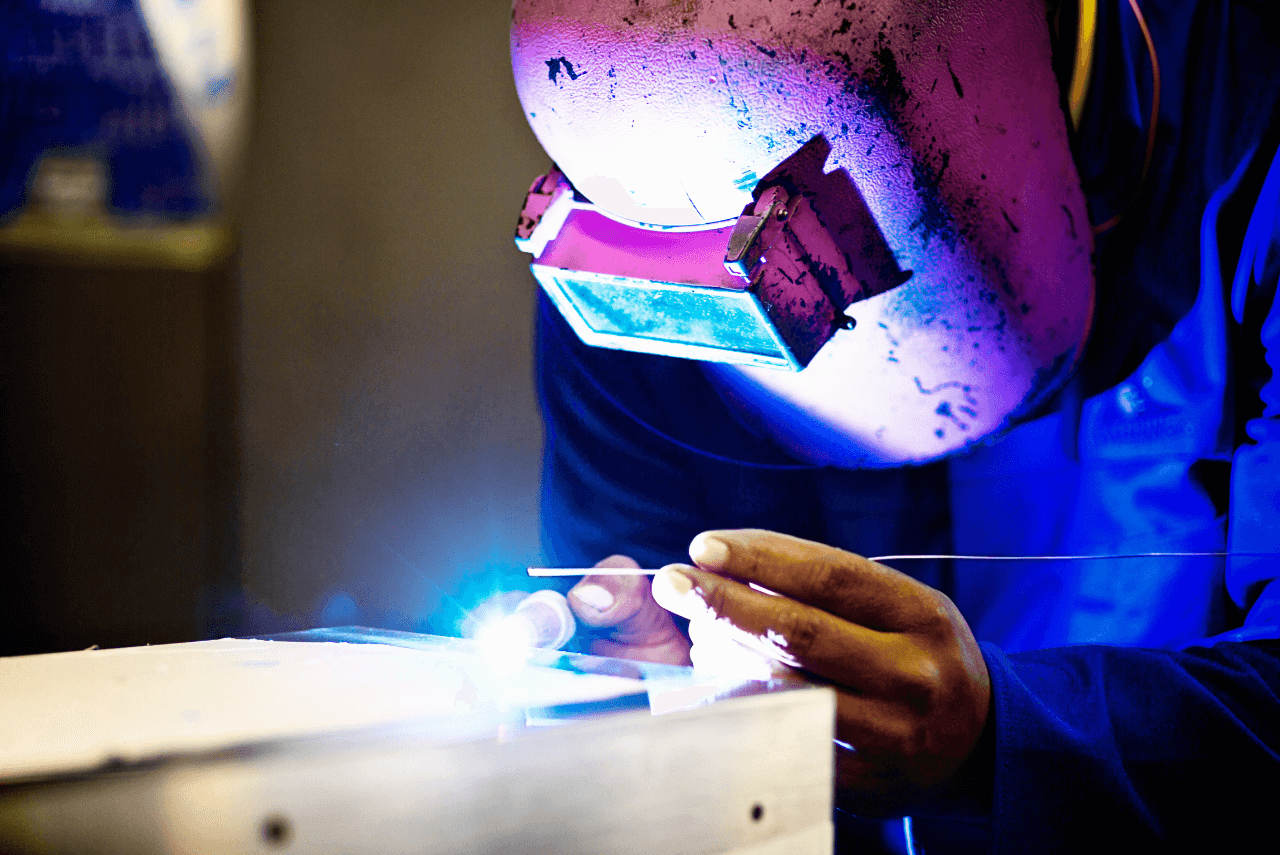

Advanced Welding Capabilities

ISO 3834 Certified

Our team of certified welders and state-of-the-art equipment enables us to offer a variety of welding solutions for aluminium, stainless steel and mild steel, including:

Welding Techniques:

- Gas Tungsten Arc Welding (GTAW)

- Gas Metal Arc Welding (GMAW / Pulse)

- Shielded Metal Arc Welding (SMAW)

- Laser Welding (material thickness: up to 3mm)

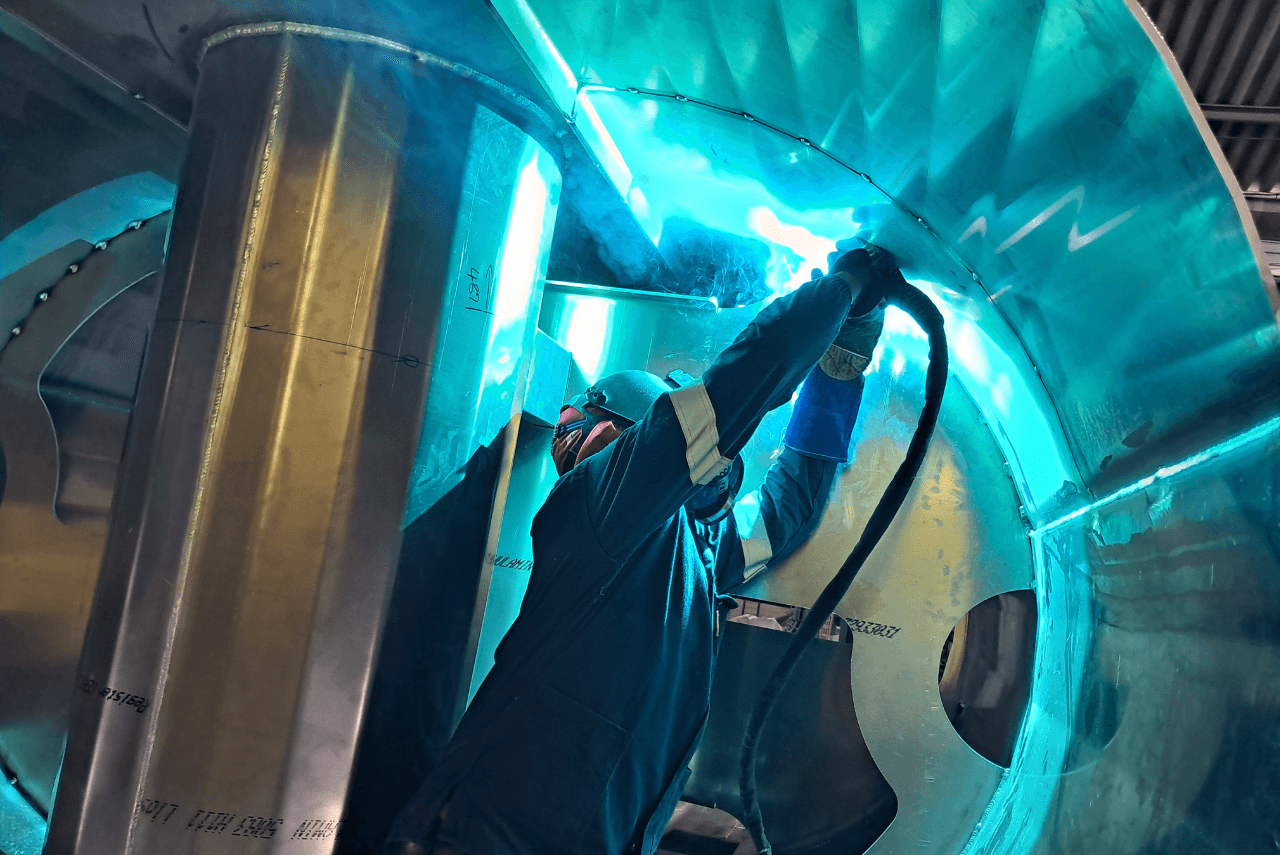

Our Equipment Includes:

- 20 Arc and TIG welders

- 10 MIG welders

- Robotic welding station (6-axis TIG & MIG)

- 500kg turn-and-tilt manipulator

- Track-mounted welding stations

- High-efficiency laser welders

Bring Your Metal Needs to Life

From sub-assemblies and batch manufacturing to advanced welding and precision drawing services, Fabrinox is here to help you meet your goals, on time and to the highest standard.

Contact Us: [email protected]